Introduction

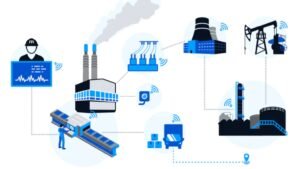

The Internet of Things (IoT) has reshaped numerous industries, but perhaps nowhere is its impact felt more strongly than in manufacturing. Factories today are not just sites for production; they are becoming smart, interconnected hubs of data and operational efficiency. The IoT is at the heart of this transformation, connecting factory systems to the cloud to enable real-time insights, predictive maintenance, and much more.

One startup, in particular, is redefining factory connectivity by offering a cloud-based IoT platform that seamlessly links machines, processes, and analytics. This game-changing platform is set to transform how factories operate in an increasingly competitive global market. So, how exactly does this IoT startup connect factories to the cloud, and what benefits does it offer? Let’s explore.

Why Factories Need Cloud Connectivity

Traditional manufacturing faces several hurdles, such as disconnected systems, manual monitoring, and delayed decision-making due to a lack of real-time data. Factories still heavily reliant on isolated legacy systems struggle to keep up with the growing demands of modern production environments.

This is where IoT comes into play. By embedding sensors into machinery and linking them to the cloud, factories can achieve:

- Real-time data insights: Factories can monitor operations as they happen, identifying inefficiencies or breakdowns before they become costly problems.

- Remote monitoring: Supervisors and engineers can track factory performance from anywhere, ensuring smooth operations even off-site.

- Predictive maintenance: IoT sensors can anticipate equipment failure, allowing for timely maintenance and reducing unplanned downtime.

Cloud integration adds an additional layer of scalability and flexibility to this connectivity, providing manufacturers with robust data analytics, storage, and processing power without the need for expensive on-premise infrastructure.

The Startup Behind the IoT Platform

One startup leading this revolution—let’s call them CloudFactory IoT—is building an innovative IoT platform designed specifically for manufacturers looking to modernize their operations. Founded by engineers and data scientists passionate about automation, CloudFactory IoT’s mission is to make industrial processes smarter, more connected, and scalable.

What makes CloudFactory IoT unique?

- Focused on ease of integration: The platform is built with compatibility in mind, ensuring it can connect to both modern machines and older legacy systems.

- Data-driven approach: The platform offers advanced analytics powered by machine learning algorithms, providing actionable insights based on real-time data streams.

- Cloud-native architecture: As a cloud-based service, CloudFactory IoT offers factories the flexibility to scale up or down according to production needs, minimizing upfront hardware costs.

How the IoT Platform Works

CloudFactory IoT’s platform is a comprehensive solution that combines the power of IoT sensors, real-time analytics, and cloud computing. Here’s how it works:

- Sensor deployment: IoT sensors are embedded in machines and equipment across the factory floor. These sensors gather data such as temperature, pressure, operational speed, and more.

- Data transmission to the cloud: The collected data is transmitted to the cloud, where it is processed in real-time using powerful analytics tools.

- Actionable insights: The platform analyzes the data and generates insights that help manufacturers make informed decisions—whether it’s adjusting machine settings for better efficiency or scheduling maintenance before a critical failure.

This system has already proven itself in various manufacturing environments. In one case, a factory using CloudFactory IoT’s platform was able to cut energy costs by 15% after analyzing operational data and identifying inefficiencies in machinery settings.

Enhancing Factory Connectivity with IoT

A significant hurdle for many manufacturers is how to integrate IoT with their existing infrastructure. CloudFactory IoT’s platform is designed with this challenge in mind. Its technology can be applied to both legacy systems and modern machines, ensuring a smooth transition to a fully connected factory.

The platform allows for:

- Cloud-enabled smart factories: Factories can be transformed into data-driven operations, where machines “communicate” with each other, optimizing workflows autonomously.

- Remote monitoring: Factory managers can oversee multiple production sites from a single dashboard, making it easier to manage operations at scale.

One real-world example comes from a manufacturer that was able to reduce downtime by 20% by using the IoT platform to monitor equipment remotely and detect minor malfunctions before they escalated.

Scalability and Flexibility for Manufacturers

Scalability is one of the biggest advantages of a cloud-based IoT platform. Whether you’re a small factory looking to optimize a single production line or a multinational corporation managing dozens of sites globally, CloudFactory IoT offers a solution that grows with your business.

For small to medium-sized manufacturers, the platform allows for low-cost entry into IoT without the need for massive upfront investments. For larger enterprises, the cloud offers flexibility to handle vast amounts of data, providing detailed analytics across multiple factories, even in different countries.

By embracing IoT connectivity, manufacturers can future-proof their operations, ensuring that their factories remain agile and competitive in an ever-evolving market.

Challenges in IoT Implementation and How the Startup Overcomes Them

Implementing IoT in a factory environment is not without its challenges. The most common barriers include:

- Cost: IoT systems can be expensive to implement, but CloudFactory IoT provides modular solutions, allowing factories to start small and expand as needed.

- Data security: With the increase in connected devices, security becomes a critical concern. CloudFactory IoT has invested heavily in encryption, secure communication channels, and regular software updates to ensure that data remains protected.

- System integration: Many factories have complex ecosystems of machinery. CloudFactory IoT solves this with its compatibility tools that allow seamless integration with a variety of machines, both old and new.

Moreover, by using AI-driven algorithms, the platform offers predictive analytics that help manufacturers not just monitor but improve their operations over time.

Conclusion

In a world where efficiency and data-driven decision-making are crucial for manufacturing success, IoT and cloud connectivity are reshaping the factory floor. With its innovative IoT platform, CloudFactory IoT is connecting factories to the cloud and driving the future of smart manufacturing.

By offering real-time insights, scalability, and seamless integration with existing systems, CloudFactory IoT is helping manufacturers transform their operations, reduce costs, and remain competitive. As more factories turn to IoT for connectivity, platforms like CloudFactory IoT will undoubtedly play a central role in the future of manufacturing.