The Internet of Things (IoT) is transforming supply chain operations into something smarter and more efficient. For industrial leaders and decision-makers, understanding how IoT in supply chain management can optimize processes is crucial.

In this post, you’ll learn about the key applications of IoT that can enhance logistical practices. By integrating IoT technologies, companies can track inventory in real-time, predict maintenance needs, and streamline transportation routes. These advancements address common challenges in supply chain management, providing solutions that lead to improved operational efficiencies.

As you explore this topic, expect to discover specific IoT applications that can redefine smart logistics. The aim here is to empower your decision-making with actionable insights that can drive your supply chain strategies forward. For further reading, check out how IoT is revolutionizing connected warehouses and learn about supply chain resilience.

Curious about real-world implementations? Watch this IoT Supply Chain video to see practical applications in action.

Understanding IoT and Supply Chain Synergy

The synergy between the Internet of Things (IoT) and supply chain management leads to unprecedented efficiency and visibility. By integrating IoT devices and technologies, businesses can track assets, monitor inventory levels, and gather valuable data in real-time. This collaboration fundamentally transforms how companies manage supply chains, reducing inefficiencies and driving smarter decision-making.

What is IoT?

The Internet of Things, or IoT, refers to a network of interconnected devices that communicate and share data over the internet. These devices include everything from sensors and machinery to vehicles and consumer devices. IoT allows these devices to collect and exchange data without human intervention.

In supply chain management, IoT plays a crucial role by enabling real-time monitoring and management of assets. For instance, sensors can track the location and condition of goods as they move through the supply chain. This level of connectivity allows businesses to respond swiftly to changes, enhance inventory management, and improve customer service. The result is a more responsive and efficient supply chain operation.

How IoT Transforms Supply Chains

IoT enhances supply chain operations by significantly increasing visibility and efficiency. Here are some ways it achieves this transformation:

-

Real-Time Data Access: IoT devices continuously collect data, allowing companies to monitor supply chain performance. This real-time information helps businesses make informed decisions about inventory levels, shipping routes, and production schedules.

-

Predictive Maintenance: Through predictive analytics, IoT devices can signal when equipment is likely to fail. This proactive approach reduces downtime and maintenance costs, ensuring that production processes remain smooth.

-

Inventory Management: Sensors can detect the quantity and condition of inventory in warehouses. This capability enables companies to maintain optimal stock levels, preventing both overstocking and stockouts.

-

Improved Logistics: IoT streamlines transportation by providing data about traffic patterns, weather conditions, and shipment statuses. This information allows businesses to optimize delivery routes and schedules, reducing delays and costs.

-

Enhanced Customer Experience: With better visibility into inventory and shipping, businesses can provide more accurate delivery estimates. This transparency enhances customer satisfaction and trust.

Incorporating IoT in supply chain operations not only addresses traditional challenges but also prepares businesses for future growth. For more in-depth insights, check out the role of IoT in enhancing supply chain visibility and explore various use cases and challenges of IoT in supply chains.

Photo by Tiger Lily

Key Applications of IoT in Supply Chain

IoT applications are reshaping supply chain management by enhancing visibility, accuracy, and efficiency. By utilizing IoT technology, companies can navigate challenges that arise during operations and create better outcomes. Here, we will explore some significant applications of IoT within the supply chain.

Real-Time Inventory Management

Real-time inventory management powered by IoT enables businesses to track inventory levels accurately. With the use of sensors and RFID tags, organizations can gain immediate insights into stock status. This capability leads to better inventory control and helps prevent cost inefficiencies caused by overstocking or stockouts.

For instance, when a product is shipped or sold, the system updates in real-time. This transparency in inventory management means organizations can reorder products promptly, ensuring they meet customer demand without delay. Enhanced inventory tracking allows companies to optimize storage costs and boost overall supply chain efficiency.

Predictive Maintenance

IoT empowers predictive maintenance, a proactive approach that anticipates equipment failures before they occur. Sensors attached to machinery can monitor performance data in real-time. This data helps identify potential issues, enabling maintenance teams to schedule repairs when systems show early signs of wear.

By reducing unexpected equipment breakdowns, companies can decrease downtime and extend the lifespan of machinery. Predictive maintenance not only promotes operational efficiency but also leads to substantial cost savings. It transforms maintenance from a reactive task to a strategic function, giving businesses a competitive edge.

Enhanced Logistics and Transportation

IoT plays a pivotal role in improving logistics and transportation processes. Smart logistics solutions powered by IoT devices collect data on traffic patterns, weather conditions, and shipment performance. This information allows supply chain managers to optimize routes and schedules, reducing delivery times and costs.

Companies can also monitor vehicle conditions, which enhances driver safety and reduces fuel consumption. For example, by analyzing vehicle performance data, businesses can modify driving behavior to minimize engine wear and improve fuel efficiency. This comprehensive visibility into logistics fosters more reliable transportation networks.

Supply Chain Analytics

The integration of IoT leads to advanced supply chain analytics, delivering crucial insights that drive data-driven decision-making. IoT devices collect vast amounts of data, which can be analyzed to identify trends and patterns. This analysis informs strategy and improves forecasting accuracy.

Organizations can utilize analytics to determine the best suppliers, optimize distribution strategies, and tailor their inventory based on customer behavior. By tapping into real-time data, businesses can make informed decisions that enhance their supply chain performance. The focus on analytics not only refines operations but also supports growth initiatives.

For further reading on IoT practices in supply chain management, check out this detailed overview that highlights various applications.

Photo by Tiger Lily

Benefits of IoT in Supply Chain Operations

Integrating IoT into supply chain operations brings multiple advantages that can significantly reshape how businesses manage their logistics. By utilizing smart devices and connected technologies, companies can enhance efficiency, reduce costs, and improve customer satisfaction. Let’s explore three key benefits that illustrate the impact of IoT in this sector.

Increased Efficiency and Productivity

IoT streamlines supply chain processes, resulting in greater efficiency and productivity. Smart devices continuously collect and transmit data, enabling businesses to monitor operations in real-time. This constant flow of information allows for quick decision-making, minimizing delays and reducing operational downtime.

For instance, with IoT sensors, companies can track the movement of goods and monitor their conditions as they travel through the supply chain. This transparency helps identify bottlenecks, optimize inventory levels, and automate reordering processes. As a result, organizations can ensure that resources are utilized effectively, leading to higher throughput without compromising quality.

Additionally, predictive maintenance powered by IoT can anticipate equipment failures before they occur. By addressing maintenance issues proactively, businesses can prevent unplanned downtime that disrupts production schedules. This proactive approach enhances overall productivity, keeps operations running smoothly, and supports a more agile supply chain.

Cost Reduction

Implementing IoT in supply chain operations creates significant cost-saving opportunities. Real-time monitoring and data analytics enable companies to make informed decisions that reduce waste and enhance resource allocation.

For example, by using IoT devices to track shipments and inventory levels, businesses can avoid overstocking or stockouts. These inefficiencies often lead to unnecessary costs, such as additional storage fees or lost sales. By optimizing inventory management, organizations can maintain lean operations and minimize expenses.

Moreover, IoT-powered logistics systems help analyze shipping routes and vehicle performance. Companies can reduce fuel usage and transportation costs by identifying more efficient delivery paths. This level of insight allows organizations to cut operational expenses while ensuring timely product delivery.

Improved Customer Satisfaction

IoT enhances customer experiences by increasing service delivery efficiency. With precise monitoring and tracking of shipments, businesses can provide accurate delivery estimates and real-time updates to customers. This transparency fosters trust and boosts customer satisfaction.

IoT also enables companies to respond quickly to customer inquiries and complaints. When businesses can access real-time data, they can address issues promptly and maintain a strong relationship with clients. Enhanced service not only strengthens customer loyalty but can also lead to positive reviews and referrals.

Moreover, by understanding customer behavior through data analytics, companies can tailor their offerings to better meet demand. This personalization contributes to a more favorable experience, leading to higher customer retention and increased revenue.

For more information on how IoT can transform supply chains, explore The Future of Manufacturing: Key Trends to Watch in 2024 and learn about Building Supply Chain Resilience Through Effective Risk Management.

Photo by cottonbro studio

Challenges in Implementing IoT Solutions

While the adoption of IoT technologies offers promising benefits for supply chain operations, several challenges can hinder their implementation. Understanding these obstacles is essential for businesses looking to capitalize on the potential of smart logistics.

Data Security Concerns

Data security is a major consideration when implementing IoT solutions in supply chains. Each device connected to the network can become a target for cyberattacks. With the sensitivity of the data collected—such as customer information, inventory levels, and operational details—businesses must prioritize safeguarding this information.

Here are some critical aspects to consider:

- Increased Attack Surface: The more devices connected to the network, the greater the vulnerabilities. Each new sensor or device can serve as a potential entry point for malicious actors.

- Data Privacy Regulations: Compliance with regulations, such as the General Data Protection Regulation (GDPR), adds another layer of complexity. Businesses must ensure that they handle personal data responsibly while implementing IoT systems.

- Preventive Measures: Companies should invest in robust cybersecurity measures. Regular software updates, encryption of data, and continuous monitoring can help mitigate risks associated with IoT devices.

For further insights on challenges related to IoT implementation, you can read more on this analysis of common IoT challenges.

Integration with Existing Systems

Integrating IoT solutions with existing supply chain technologies presents significant challenges. Businesses often utilize legacy systems that may not seamlessly connect with modern IoT applications.

Consider the following integration hurdles:

- Compatibility Issues: Many legacy systems require tailored adjustments to work with new IoT devices. These adjustments can be time-consuming and costly.

- Data Silos: Disparate systems may lead to information silos, where valuable data is isolated in different departments. This fragmentation complicates decision-making and reduces operational efficiency.

- Training and Change Management: Employees must be trained to use new IoT systems effectively. Resistance to change can further impede integration efforts as teams adjust to new workflows.

Companies seeking to enhance integration strategies may benefit from exploring successful case studies and expert insights on automation and logistics.

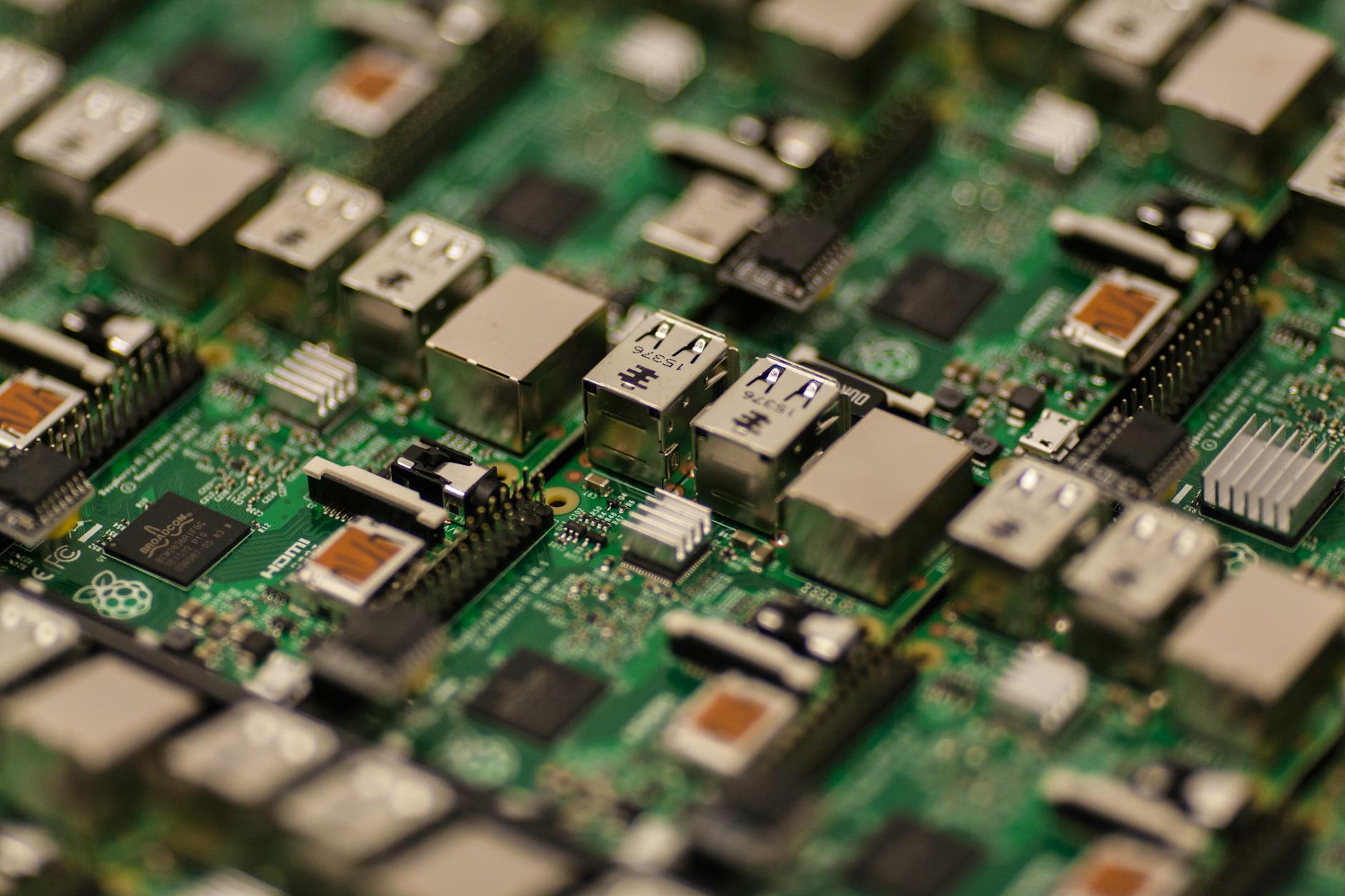

Photo by Craig Dennis

Future Trends of IoT in Supply Chain

IoT is continually evolving, shaping the landscape of supply chain operations. As technology advances, different trends are emerging. Let’s explore how these trends will impact supply chains moving forward.

Artificial Intelligence and IoT Convergence

The convergence of Artificial Intelligence (AI) and the Internet of Things (IoT) is revolutionizing supply chain management. By integrating AI into IoT applications, companies enhance operational intelligence and decision-making capabilities.

AI empowers IoT devices to analyze vast amounts of data collected from various sources. This capability enables businesses to identify patterns and predict outcomes with more accuracy. For instance, machine learning algorithms can process historical data from sensors in machinery, predicting failures before they occur. This predictive maintenance reduces downtime and minimizes costs associated with unexpected breakdowns.

Moreover, AI-driven analytics can optimize inventory management. By analyzing consumption patterns, organizations can adjust inventory levels in real-time, avoiding overproduction and stockouts. This integration ensures that businesses have the right products available at the right time, catering to customer demands efficiently.

To learn more about AI’s role in this area, check out AI and IoT are Redefining the Future of Supply Chains.

Photo by Tiger Lily

Sustainability and IoT

Sustainability is a growing concern in supply chain management, and IoT technologies are key to addressing this challenge. By utilizing IoT devices, companies can monitor and manage their environmental impact more effectively.

IoT systems help track energy consumption, resource usage, and waste production in real time. For instance, sensors can monitor temperature and humidity in warehouses, ensuring optimal conditions for goods. This not only preserves product quality but also reduces energy waste.

Additionally, IoT enables better logistics planning, which leads to lower carbon emissions. By providing data on traffic patterns and delivery routes, businesses can optimize transportation, minimizing fuel consumption. This commitment to sustainability not only reinforces brand reputation but also complies with regulatory demands.

Companies focusing on sustainable practices can explore insights on Sustainable Supply Chain: Reducing Carbon Footprints.

Understanding these trends is crucial for businesses aiming to stay competitive in the market. By harnessing the power of AI and IoT, and prioritizing sustainability, companies can create more efficient and responsible supply chains.

Conclusion

Understanding the role of IoT in supply chain management is essential for modern businesses aiming for operational excellence. With its various applications, IoT technologies foster streamlined processes, real-time data access, and improved decision-making capabilities. These elements collectively contribute to smarter supply chain operations.

Key Takeaways

-

Real-Time Insights: IoT devices provide immediate data on inventory levels, transportation conditions, and equipment status. This real-time monitoring enhances responsiveness to market needs.

-

Efficiency Gains: Implementing IoT can lead to significant enhancements in resource management. Organizations can reduce waste, optimize routes, and improve overall productivity.

-

Customer Satisfaction: Enhanced visibility in the supply chain allows businesses to offer accurate delivery estimates and maintain optimal inventory levels. This transparency builds trust and loyalty among customers.

-

Strategic Decision-Making: Advanced analytics driven by IoT data can inform strategic choices in procurement, logistics, and inventory management, fostering data-driven decisions across the organization.

-

Sustainability: IoT can support sustainability initiatives. Companies can monitor their carbon footprint, energy use, and waste production, aligning their operations with environmental goals.

By recognizing these advantages, businesses can leverage IoT capabilities to address their unique supply chain challenges. Ultimately, embracing IoT technologies positions companies to thrive in an increasingly competitive marketplace. For further insights into how IoT reshapes supply chains, explore resources like IoT in Supply Chain Management and Logistics for Success and Top 10: Uses of IoT in Supply Chains.

Photo by Tiger Lily