Introduction

The manufacturing industry is undergoing a massive transformation. As we move into 2024, technological advancements, sustainability goals, and the need for resilient supply chains are reshaping how manufacturers operate. For businesses to stay competitive, it’s crucial to keep an eye on the trends that are driving these changes. Whether it’s the adoption of smart technologies, embracing sustainability, or navigating workforce shifts, the future of manufacturing is dynamic and full of opportunities.

Technological Advancements Driving Manufacturing

The Rise of Industry 4.0 and Smart Factories

Industry 4.0 continues to evolve, with smart factories becoming more prevalent in 2024. The integration of Internet of Things (IoT) devices, artificial intelligence (AI), and machine learning is transforming how factories operate. These technologies enable manufacturers to optimize production lines, monitor equipment in real time, and predict maintenance needs. Smart factories not only improve efficiency but also reduce downtime and costs, giving businesses a competitive edge in the global market.

Robotics and Automation in 2024

Automation has been a significant force in manufacturing for years, but in 2024, we’re seeing a surge in robotics and collaborative robots (cobots). Cobots are designed to work alongside human workers, performing repetitive tasks while allowing humans to focus on more complex activities. Their increased adoption across industries is improving productivity and worker safety. With robots becoming more sophisticated, they’re handling intricate assembly processes, improving accuracy, and reducing human error.

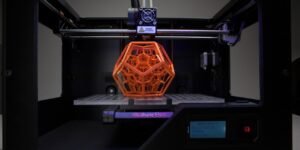

3D Printing and Additive Manufacturing

Additive manufacturing, especially 3D printing, is no longer limited to prototyping. In 2024, it is being adopted for full-scale production, enabling manufacturers to produce complex, customized products with shorter lead times. The ability to create parts on demand reduces the need for large inventories, lowering storage costs. Industries such as aerospace, automotive, and healthcare are especially benefiting from the agility and flexibility that 3D printing offers.

Sustainable Manufacturing: A Growing Priority

Green Manufacturing Practices

As sustainability becomes more than just a buzzword, green manufacturing is emerging as a critical trend in 2024. Companies are investing in energy-efficient machinery, adopting renewable energy sources, and developing manufacturing processes that reduce waste. For instance, some manufacturers are incorporating closed-loop systems, where waste materials are recycled back into production. This not only helps the environment but also lowers operational costs in the long run.

Reducing Carbon Footprint in Manufacturing

In response to stricter regulations and growing consumer demand for eco-friendly products, manufacturers are increasingly focused on reducing their carbon footprint. By transitioning to cleaner energy sources such as solar or wind, companies can significantly cut their emissions. Government incentives and penalties for non-compliance are also pushing businesses toward adopting greener practices. Achieving sustainability goals is no longer optional; it’s a business imperative.

Supply Chain Transformation and Resilience

Digitalization of the Supply Chain

Supply chains have been under significant pressure in recent years due to global disruptions, making supply chain digitalization a top priority in 2024. Real-time tracking, powered by IoT and advanced data analytics, allows manufacturers to monitor every aspect of their supply chains, from raw material sourcing to delivery. Digital twins—virtual models that replicate physical supply chains—are helping companies simulate different scenarios and make better decisions. Moreover, blockchain technology is playing a crucial role in enhancing transparency, security, and traceability within the supply chain.

Reshoring and Regionalization

With global supply chains facing ongoing challenges, many manufacturers are turning to reshoring—bringing production back to domestic or regional locations. This trend has been fueled by the need to reduce risks associated with long-distance shipping and reliance on foreign suppliers. Reshoring also helps mitigate the impact of trade tariffs and geopolitical tensions, offering more control over production timelines and quality. By focusing on regionalization, manufacturers can create more resilient supply chains, ensuring continuity even in times of crisis.

Workforce Changes in Manufacturing

Skills Gap and Workforce Development

As automation and AI take center stage, the manufacturing workforce is facing a significant skills gap. There’s a growing need for workers skilled in emerging technologies like robotics, data analytics, and AI. Traditional manufacturing jobs are evolving, requiring a new skill set to manage and maintain advanced machinery. Upskilling and reskilling are becoming essential for workers to adapt to the changing industry landscape. In response, many companies are investing in training programs to prepare their employees for the future of manufacturing.

Human-Robot Collaboration

The rise of cobots is redefining the relationship between humans and machines in the workplace. These robots work alongside human employees, enhancing their capabilities rather than replacing them. For example, cobots can handle heavy lifting and repetitive tasks, while humans focus on decision-making and quality control. This collaboration between humans and robots is improving workplace safety, reducing fatigue, and boosting overall productivity.

Conclusion

The future of manufacturing is evolving rapidly, with key trends in technology, sustainability, and workforce dynamics leading the charge. Industry 4.0, green manufacturing practices, and the reshaping of supply chains are transforming the landscape, while the workforce adapts to new roles alongside automation. Manufacturers that embrace these changes will be better positioned to thrive in 2024 and beyond. Now is the time for businesses to invest in the latest technologies, sustainable practices, and workforce development to stay competitive and resilient in an ever-changing world.