The efficiency of warehouse operations plays a critical role in the overall success of a company. An optimized warehouse layout is not just about storing as much inventory as possible; it’s about strategically organizing your space to streamline operations, reduce costs, and ensure faster order fulfillment. With the right layout, your staff can locate and pick items more easily, minimize handling time, and even enhance employee safety and satisfaction.

In this article, we’ll dive into how warehouse automation and layout optimization can help you maximize efficiency, reduce errors, and improve productivity, turning your warehouse into a powerhouse for growth.

Understanding Warehouse Layout Optimization

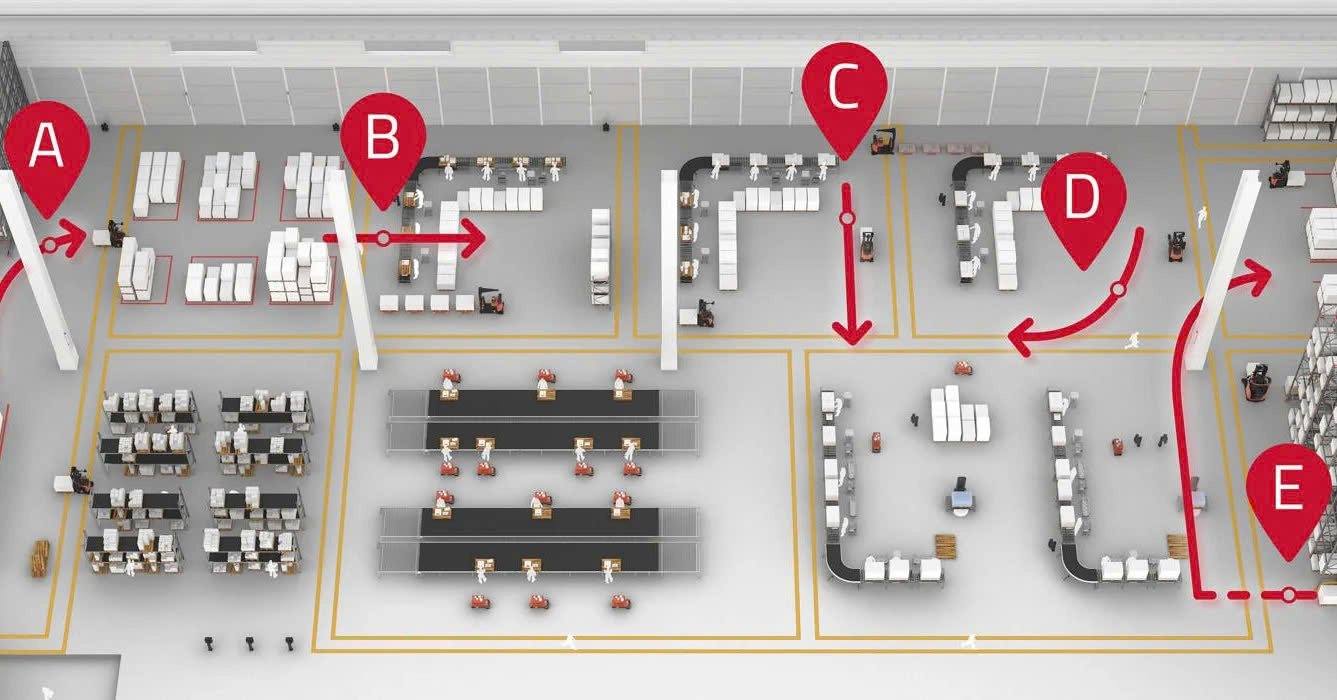

Warehouse layout optimization involves organizing storage, handling, and processing areas to maximize efficiency. It directly impacts how fast and accurately orders are fulfilled, how inventory is managed, and how well your business meets customer expectations.

Here are some of the most critical benefits:

- Improved Workflow: An efficient layout ensures goods move logically through the warehouse, from receiving to storage, picking, and shipping. This reduces handling time and prevents errors.

- Space Maximization: Optimize the use of floor and vertical space to store more inventory within the same footprint, delaying or avoiding costly expansion.

- Increased Productivity: A smart layout reduces travel time and physical strain on staff, speeding up order processing and boosting productivity.

- Enhanced Safety: A well-organized warehouse reduces clutter and safety hazards, ensuring compliance with safety regulations and reducing accidents.

- Scalability: An optimized layout is flexible, allowing easy adjustments as your business grows or product lines evolve.

Key Factors to Consider for Warehouse Layout Optimization

When planning your warehouse layout, consider these key elements to ensure a more efficient, productive, and safe operation:

- Space Utilization

- Maximize vertical space with appropriate shelving and racking systems.

- Optimize floor space by arranging aisles, docks, and work areas to facilitate smooth movement and workflow.

- Workflow Optimization

- Streamline the movement of goods from receiving to shipping by eliminating bottlenecks.

- Organize inventory into zones based on frequency, size, or special handling needs to reduce travel time.

- Accessibility

- Position frequently accessed items closer to shipping areas to minimize retrieval time.

- Ensure the layout supports efficient use of material handling equipment, allowing adequate space for safe maneuvering.

- Scalability

- Design your layout with future growth in mind by using modular shelving and racking systems that can be easily adjusted.

- Ensure the layout is flexible enough to accommodate technology upgrades and changes in demand.

- Safety and Compliance

- Incorporate clear signage, safety barriers, and designated pedestrian pathways to ensure a safe working environment.

- Make sure your layout adheres to safety and fire regulations.

Steps to Optimize Your Warehouse Layout

Optimizing your warehouse layout is a multi-step process. Here’s a step-by-step guide to help you achieve maximum efficiency:

- Assess Current Layout and Identify Pain Points

- Conduct a thorough evaluation of your current layout, identifying inefficiencies and workflow challenges.

- Gather feedback from warehouse staff to uncover practical issues and areas for improvement.

2. Plan According to Inventory and Demand

- Use data to understand inventory levels and demand patterns, guiding your layout redesign.

- Implement inventory categorization (e.g., ABC analysis) to prioritize item placement based on pick frequency.

3. Design for Efficiency and Flexibility

- Create a layout with a unidirectional flow from receiving to shipping to minimize unnecessary movement.

- Use modular equipment and mobile shelving to adjust your layout as business needs change.

4. Incorporate Technology and Automation

- Implement a Warehouse Management System (WMS) to optimize storage locations, picking paths, and inventory tracking.

- Explore warehouse automation options like conveyor belts, automated storage and retrieval systems (AS/RS), and robotic pickers to further streamline operations.

5. Test and Iterate

- Use software simulations to model your new layout and identify potential issues before implementation.

- Continuously refine the layout based on performance data and employee feedback.

Best Practices for Warehouse Layout Optimization

- Regular Review and Adjustment: Periodically review your layout and make adjustments based on current operations and inventory levels to maintain efficiency.

- Employee Training: Engage your warehouse team in the optimization process to ensure they understand the new layout and can work efficiently within it.

- Sustainability: Incorporate energy-efficient lighting and sustainable materials into your warehouse design to reduce your carbon footprint and operational costs.

Leveraging Automation for Warehouse Layout Optimization

When it comes to warehouse optimization, automation can be a game-changer. Uphance offers a suite of features designed to streamline operations and maximize efficiency. Here’s how automation can transform your warehouse:

- Customizable Layouts: Uphance’s WMS allows you to mirror your physical warehouse structure, setting up aisles, rows, shelves, and bins to optimize space and accessibility.

- Visual Management Tools: Visually design your warehouse layout to plan and organize storage areas, identifying opportunities to maximize space utilization.

- Automated Storage Suggestions: Uphance’s intelligent putaway system recommends optimal storage spots for new inventory, ensuring efficient retrieval and space utilization.

By combining automation with an optimized warehouse layout, you can enhance your picking process, reduce errors, and boost overall efficiency.

Conclusion

Optimizing your warehouse layout is a strategic process that drives operational excellence. By carefully considering factors like space utilization, workflow optimization, accessibility, and safety, you can design a warehouse that improves productivity, safety, and scalability.

Integrating automation tools like Uphance’s WMS further enhances efficiency, enabling you to manage inventory in real-time and streamline workflows. As your business evolves, so should your warehouse layout—remaining adaptable is key to staying competitive in today’s fast-paced market.